Table of Contents

TYPES OF WEBS:

There are several different sorts of web – the sheet web, orb web, tangle web, funnel web, tubular web and dome or tent web. The most common type of web that is seen around the home is the orb web, so called because of its circular shape, resembling a giant wheel. It is an immensely strong web, I have seen a video of a bat being caught in an orb web and consumed by a common garden orb weaver.

Several different types of silk may be used in web construction, including a “sticky” capture silk, or with “fluffy” capture silk, depending on the type of spider. Webs may be in a vertical plane (most orb webs), a horizontal plane (sheet webs), or at any angle in between. Most commonly found in the sheet-web spider families, some webs will have loose, irregular tangles of silk above them. These tangled obstacle courses serve to disorient and knock down flying insects, making them more vulnerable to being trapped on the web below. They may also help to protect the spider from predators such as birds and wasps.

Click here for a page with videos of web construction.

Types of Spider Webs

Besides the orb webs, other web designs are used by different species. The net-casting spider, Deinopsis, constructs a web between her forelegs and hangs head down waiting for an insect to pass. The web is thrown over the victim and entangles it. The Bolas spider also has a special catching technique. As the name may suspects she throws the thread with an adhesive bubble at the end to her prey. The prey is decoyed by chemical substances (pheromones).

The trapdoor spider hides in a tunnel that can be closed with a door. If the prey walks over a signal thread the door is opened and the spider grabs it. Funnel weaver spiders spin a horizontal mat and wait in a funnel at the end for their prey to come along.

The Linyphiidae and Theridiidae to which the redbacks and black widow belongs use three-dimensional tangled web. Linyphiidae makes a horizontal dense sheet web with a lot of non-adhesive threads above it. If an insect flies against a thread it tumbles onto the mat and is grabbed. The Theridiidae construct a messy space web in which the prey is entangled.

HOW SPIDERS MAKE WEBS:

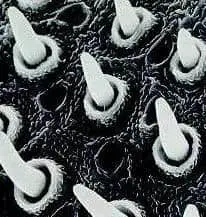

Spiders have several spinnerets at the base of their abdomen. Every gland produces a thread for a special purpose. There are seven different known glands. Each spider possesses only some of these glands and not all seven together. Normally a spider has three pairs of spinnerets, but there are spiders with just one pair or as many as four pairs of spinnerets, with each spinneret having its own function.

The average diameter of a thread in a orb web is around 0.15 mm. The smallest measured thread was only 0.02 mm thick. We are able to see the web only because of the reflection of sunlight on the thread. These thin wires are capable of stopping a bee flying at full speed. This thread is not only strong but also very elastic. The thread of the orb web spider Araneus diadematus is very elastic and can be stretched 30 – 40% before it breaks. Steel can be stretched only 8% and nylon around 20%.

Orb weaving spiders make their webs at night time and usually take them down in the morning. They eat the silk, leaving only the base line to rebuild on. Constructing the web uses a lot of the spider’s energy due to the large amount of protein required, in the form of silk and after a time the silk will lose its stickiness and becomes inefficient at capturing prey. Eating their web is a way for the spider to recoup some of the energy used in spinning. The silk proteins are thus ‘recycled’.

To create the initial base line, the spider uses the wind to carry its initial sticky thread. The silk is released from its spinnerets and carried by the wind to a suitable surface. When it sticks to a surface the spider will carefully walk over the thread and strengthen it with a second thread. This process is repeated until the primary thread is strong enough to support the rest of the netting.

After strengthening the first thread, the spider will continue to make a Y shaped netting. The first three radials of the web are now constructed. More radials are added making sure that the distance between each radial is small enough to cross. This means that the number of radials in a web directly depends on the size of the spider plus the size of the web.

After the radials are complete the spider will strengthen the centre of the web with about five circular threads.

Then a spiral of non-sticky, evenly spaced, circular threads are made for the spider to easily move around its own web during construction. Then, beginning from the outside in, the spider will methodically create the adhesive spiral threads. It will use the initial radiating lines as well as the non-sticky spirals as guide lines. The spaces between each spiral will be directly proportional to the distance from the tip of its back legs to its spinners. The spider uses its own body as a measuring/spacing device. While the sticky spirals are formed, the non-adhesive spirals are removed as they are not needed any more.

After the spider has completed its web, it will chew off the initial three centre spiral threads then sit and wait with its head down, in the web for its prey to come along. If the web is broken without any structural damage during the construction, the spider does not try to remake it as this would use up too much energy and it will probably be taken down in the morning or repaired the next night.

These are the stages in building an orb web. Garden Orb Weavers can build this web overnight and then takes it down the next morning only to build it all again the next night!!

Below are some photos of orb webs.

USES FOR SPIDER SILK:

Spider silk was and is used for several applications. In olden times, it was packed in wounds to stoop bleeding. Polynesian fishermen use the thread of the golden orb web weaver Nephila as fishing line. In the New-Hebrides spider web was used to make nets for the transportation of arrow points, tobacco and dried poison for the arrow points. Some tribes in New-Guinea used webs as hat to protect their head from the rain.

During World War II the threads of Araneus diadematus, Zilla atrica, Argiope aurantia and other orb weavers were used as hairs in measuring equipment. The Americans used the threads of the black widow (Latrodectus) in their telescopic gun sights.

In 1709 a Frenchman, Bon de Saint-Hilaire, demonstrated the possibility of making fabric from silk. Many cocoons were boiled, washed and dried and the thread was collected with fine combs. Some socks and gloves were produced. A study to the economic yield of this method revealed that this would never be profitable. It was calculated that 1.3 million spider cocoons were needed to produce one kilogram of silk.

In Madagascar there were some attempts to milk Nephila’s for the production of silk. A thread was pulled out of the spinner of the spider by hand. If the spiders silk was exhausted, she was put back in the forest and the next spider was milked. The gathered silk had a beautiful golden colour. This project was also banned because of many problems.